Expertise

Handing orders using spreadsheets can suffice initially, but as your company expands, it can create errors, hold-ups, and disgruntled clients. Visualize operating an internet shop such as Vintage Visions—what once was basic monitoring becomes a disarray of outdated inventory figures and lost orders.

In this scenario comes the importance of an Order Management System or OMS. It typically means speeding up the operation of the order while introducing much accuracy in taking care of processing and fulfilling customer orders with much better customer satisfaction.

This article will illustrate to readers the definition of an order management system as well as its processes and benefits and then move on to the best practices.

What is an Order Management System?

An Order Management System (OMS) is a software application that controls the entire order process, from order placement through fulfillment and following sales service. It helps businesses monitor orders, control inventory, and facilitate timely deliveries.

In the past, companies used spreadsheets and manual updates to enter orders, but this method soon became ineffective for scaling businesses. An OMS will eliminate errors; reduce delays; and consequently enhance the client's satisfaction by automatic handling of key steps.

With an OMS, businesses can:

- Streamline order fulfillment – Automatically route orders for shipping or in-store pickup.

- Real-time inventory – Never run out of stock and backorder.

- Customer lifecycle management – Handles returns an entire after-sale support.

- Performance analysis – Track key metrics such as order processing time and shipping costs.

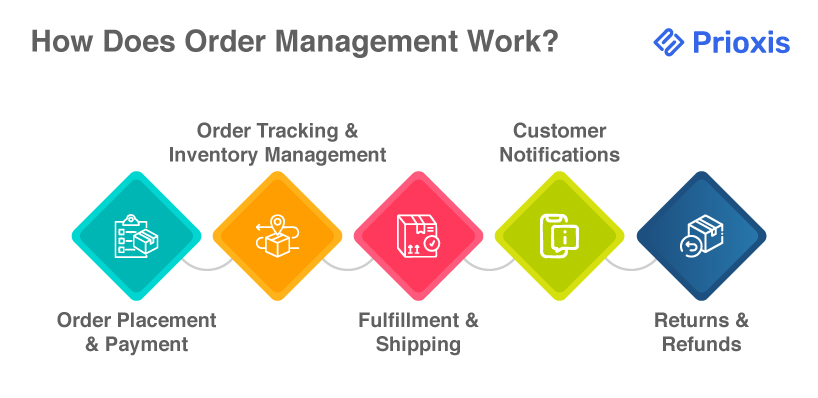

How Does Order Management Work?

Order management is the process of efficiently tracking and fulfilling customer orders. An Order Management System (OMS) streamlines this process by combining order placement, inventory management, fulfillment, and returns into a single, centralized platform.

Here's how an OMS works:

- Order Placement & Payment – Customers place orders via an online store, marketplace, or other sales channels. Payments are automatically processed.

- Order Tracking & Inventory Management – Inventory is updated in real-time to ensure timely stock levels and avoid overselling.

- Fulfillment & Shipping – Orders are shipped to the closest fulfillment center or warehouse for speedy fulfillment and shipping.

- Customer Notifications – The system gives customers real-time tracking updates, enhancing transparency and minimizing support requests.

- Returns & Refunds – If something is to be returned, the OMS facilitates the process efficiently, gathering information for better sales in the future.

By integrating with supply chain software applications, it facilitates quick and trouble-free order fulfillment end to end.

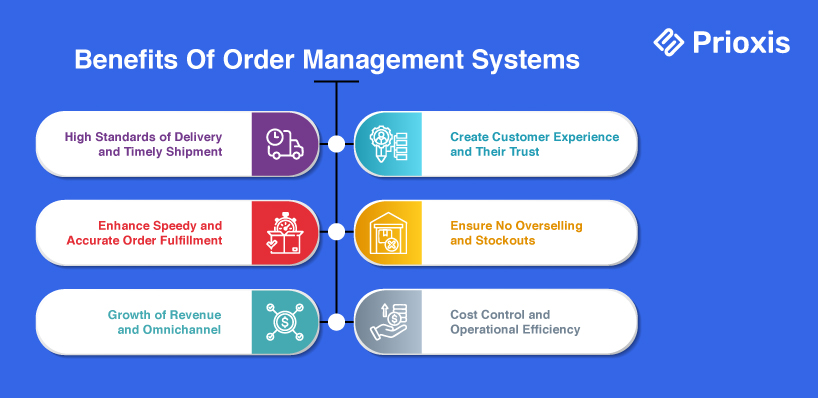

Benefits Of Order Management Systems

Listed below are some of the benefits:

1. Growth of Revenue and Omnichannel

One more benefit of an OMS is that it provides multi-channel support-even for e-commerce order management system stores, marketplaces, and physical retail locations. This means a business with up-to-date inventory across all channels will be able to optimize its sales based on inventory actualities, leaving no lost opportunity in the sales process because of stock inconsistencies.

2. Create Customer Experience and Their Trust

With real-time order and inventory tracking, the customers benefit through the receipt of real-time information regarding order status, shipping details, and expected delivery dates. Such transparency increases trust and avoids most of the customer service inquiries linked with orders.

3. Ensure No Overselling and Stockouts

Real-time inventory tracking using an OMS helps in preventing situations of overselling and relatively reduces cancellations of orders due to unavailability of stock. Businesses can make accurate forecasts of demand and arrange stocks of the right products, at the right locations.

4. Enhance Speedy and Accurate Order Fulfillment

Automated workflow minimizes manual errors to ensure quick processing of orders with accuracy. An advanced OMS applies Distributed Order Management (DOM): order routing to the most accessible fulfillment location reduces shipping costs and time.

5. Cost Control and Operational Efficiency

With an OMS integrated into Warehouse Management Systems (WMS), transportation management, and web-based rate shopping tools, cost-effective order routing is complemented further by minimizing logistics costs and maximum efficiency. Therefore, it facilitates a cost-effective handling and shipping process for the organization.

6. High Standards of Delivery and Timely Shipment

Fast and reliable shipping is what customers crave. An OMS does all these when automating fulfillment processes and coordinating carriers to deliver highly accurate orders right on time-more customer retention and a good brand image.

Challenges in Order Management System

Without an Order Management System (OMS), the following problems are common in organizations:

- Manual Processing of Orders and Errors

Manual entry, validation, and fulfillment processes present a greater chance of mistakes, delays, and inconsistencies. Order mismanagement occurs, which makes customers unhappy and results in lost opportunities for revenue.

- Not Having Real-Time Inventory Visibility

Without a centralized system, goods' inventories are hard to track across different locations and sales channels. Such mismanagement of inventories across timelines can lead to stock shortages, overstocks, and missed sales opportunities.

- Order Fulfillment Problems

Manual fulfillment processes like picking, packing, and shipping suffer from delays and inaccuracy. The absence of automated workflows allows shipping mistakes, delays in order processing, and costs for businesses to keep mounting.

- Bad Customer Experience

Order delays, misinformation about inventories, and absences of order tracking functionalities sour any customer's satisfaction. Frustrated customers are more likely to abandon purchases, write bad reviews, and take their business elsewhere.

- Constrained in Scale

As businesses expand, they become more complex to manage with larger order volumes, growing product lines, and ever-expanding sales channels. Without a robust OMS, these business operations become taxing on resources for operations, slowing down fulfillment, and resisting the land of their growth potential.

- Lack of Multichannel Coordination

Without an OMS, businesses struggle to synchronize orders and inventory across online stores, marketplaces, and physical locations. This lack of coordination leads to order discrepancies, fulfillment delays, and inventory mismatches.

- Disconnection Between Sales Agents and Digital Tools

Disconnected systems reduce the ability of sales teams and online platforms to operate in concert. Lack of integration results in false communication, inconsistent pricing, and processing errors that hinder business efficiency.

- Shipping and Logistics Management Made Complicated

Managing shipping schedules, coordination with carriers, and complex orders are likely to result in delays and errors in delivery when performed manually. A business operating without an OMS may have complications with routing orders, high shipping cost implications, and missed delivery windows.

- Inefficient Integration of Third Parties

Most businesses depend on third-party logistics (3PLs) to fulfill orders. The lack of an OMS makes it very challenging to integrate these providers seamlessly, creating delays, errors, and miscommunication between the warehouses and the sales channels.

- Limited Reporting and Analytics

Businesses rely on real-time data, insights, and performance reports to determine whether orders are successful, where bottlenecks lie, and how to refine their strategies. The absence of analytics disables data-driven decisions and makes it harder to improve efficiency and profitability.

Must-Have Features In Your Bespoke Order Management System

Below are the necessary Order Management System Features that must be included:

1. Automated Order Management

As labor cost increases and speed is called for, the necessity of automation arises. In doing so, an advanced OMS will always interface for automatic routing, processing, and fulfillment of orders-all minimizing manual input, fast-tracking order flow, bettering inventory management, and refining tracking.

2. Order Orchestration for Omnichannel Fulfillment

Fulfillment for all orders through all sales channels-online stores, marketplaces, and physical stores-is a must-have. Order orchestration ensures that all orders shall be appropriately routed to the respective fulfillment centers, warehouses, or drop ship suppliers, hence optimizing shipping costs and delivery times with very minimal errors.

3. Bundle Breakdown for Accurate Fulfillment

Product bundling and kits serve as marketing strategies for many companies. Therefore, an OMS with good bundle breakdown functions will permit companies to decompose a bundled product into individual items for picking, packing, and shipping, thus increasing the accuracy and efficiency of order fulfillment while decreasing fulfillment errors and hence improving customer satisfaction.

4. Perpetual Updates for Real-Time Data Accuracy

Real-time inventory visibility allows for nimble decision-making. Perpetual updates are the mechanism wherein companies ensure that the information about inventory levels, order statuses, and customer data remains up-to-date. This helps avoid any potential stockout situations, reduce cases of overstock or excess inventory, and ensure stock availability at all times across the sales channels.

5. Reporting and Analytics Comprehensive

In 2024, data-driven decision-making is the key differentiator. A modern OMS should include sophisticated reporting features that offer insight into the following:

- Sales trends and customer behavior

- Inventory performance and stock levels

- Order accuracy and fulfillment rates

Businesses that utilize insights from such analytics will be able to streamline business operations, spot opportunities for growth, and take preemptive action against threats.

6. Seamless Integrations for a Connected Ecosystem

A best-in-class OMS must seamlessly integrate with ecommerce platforms, shipping carriers, accounting software (e.g. QuickBooks), ERP systems, and third-party logistics (3PL). With seamless APIs for integration, information will flow freely between all tools and minimize manual data entry and inefficiencies.

How to Choose the Right OMS

Here is a stepwise guide for making the best choice:

1. Identify Your Reasons and Aims

Before going through any OMS options, firstly, identify your requirements from the business and your reason for:

- Is there a need to automate this for less manual order processing?

- Do you wish to allow real-time inventory tracking in conjunction with multiple sales channels?

- Have to integrated existing platforms, like ERP, CRM, or order management system software, seamlessly?

All such needs will refine your focus toward OMS types that best fit your business strategy.

2. Create Expansion Plan

A proper proposal plan synchronizes the members of your group on all the priorities and must-have features. The proposition should include:

- Business problems you want to solve

- Core functions you want an OMS to have

- Cost parameters

- Option of scalability and further extension

Thus, this proposal will act as a blueprint while making comparisons of the various options available in the market.

3. Compare Other Options in the Market

Research and benchmark other OMS providers against:

- Features and function

- How user-friendly and customizable for its users

- Ability to integrate with third-party tools

- Pricing models: upfront, subscription, or usage-based

- Customer support and SLAs

Read reviews and case studies to discover real-life testimonials on how each solution performs in the market.

4. Schedule Demonstrations and Trials

Before finalizing anything, schedule a demo and free trial to test the usability and performance of the system. The trial involves:

- How intuitive the interface

- Efficiency of order processing, tracking

- Real-time update accuracy on inventory

- Reporting and analytical tool effectiveness

Feedback gathering has to include your team, ensuring an excellent meeting for operational requirements.

Conclusion

A strong Order Management System (OMS) is crucial for streamlined order processing, accurate inventory control, and streamlined fulfillment across multiple channels. Integrated with ERP systems, it becomes more efficient by linking order management to CRM, supply chain, and accounting Software Solutions.

By selecting the correct OMS with automation, real-time monitoring, and frictionless integrations, companies can eliminate errors, become more efficient, and grow seamlessly, with a better customer experience and a competitive advantage.

01What is the difference between ERP and OMS?

An Enterprise Resource Planning (ERP) system links different business functions, such as finance, HR, supply chain, and sales, into an integrated business management solution. An OMS deals with order processing, inventory visibility, and order fulfillment.

02What is an Order Management System (OMS)?

An Order Management System (OMS) is software that enables enterprises to process, monitor, and complete orders proficiently through a variety of selling channels. An OMS system controls inventory levels, streamlines order processes, and provides flawless order fulfillment to deliver better customer experience and higher operational efficiency.

03What is the difference between OMS and CRM?

An OMS is concerned with order management, inventory, and fulfillment to facilitate seamless processing and delivery. A Customer Relationship Management (CRM) system, however, is intended to handle customer interactions, sales pipelines, and support services to maximize relationships and retention. While OMS streamlines order handling, CRM maximizes customer engagement.