Expertise

Still getting around managing stocks using an outdated piping system of tracking with spreadsheets? You're not alone. Keeping stock levels, forecasting demand, and avoiding shortages are tasks that can quickly become overwhelming—particularly as businesses start to grow. That is why cloud inventory management comes in.

This is all made possible by real-time tracking, automation, and exceptional integration wherein a cloud system changes the way businesses control their stock, making operations efficient as well as error-free. Be it a retailer or manufacturer or an e-commerce business, having the right system allows improved accuracy, a streamlined supply chain, and growth.

But how can you develop a Cloud inventory software that meets your needs? Explore the essential steps, key features, and best practices, and you'll be equipped to build an intelligent, scalable solution.

What is a Cloud-Based Inventory Management System?

A cloud-based inventory management system would allow an organization to track, manage, and optimize its inventory in real time using online information technology. With cloud-based inventory management software, there has been a big shift from the traditional methods where records were kept manually or using on-premise Cloud inventory management software, to being kept online under a secured environment for all inventory data.

There will be less human error with a cloud-based inventory management system, improved efficiency, and all the costs of scaling operations without headaches caused by the old manual processes. Whether a retailer, wholesaler, or manufacturer, this technology still delivers the flexibility and precision it takes to remain competitive within the fast pace of the current market.

How Cloud Inventory Management Works

Gone are the days of unflinching spreadsheets and painstaking manual stock checks. Cloud-based inventory management systems have revolutionized how businesses track, manage, and optimize their inventory. Here's how:

1. Centralized Database

A cloud-based inventory system collects and consolidates data from multiple locations- whether from warehouses, retail stores, or suppliers- into a single, universally accessible platform. This allows businesses to:

- Track inventory levels across multiple locations in real time.

- Get a glimpse of things such as purchase orders, stock allocation, and supply chain insights, all from one dashboard.

- Make informed decisions on restocking or redistributing inventory.

For instance, if you have warehouses in various cities, the cloud will ensure that all inventory data is updated and synced across locations, preventing overstocking or stockouts.

2. Real-Time Visibility

Any transaction, whether it's a sale, return, or incoming shipment, is updated instantly in the system. This closely real-time tracking with inventory gives businesses:

- The ability to set up automated alerts for low stock levels.

- Stockout prevention through timely replenishments.

- Monitoring of product movement with real-time sales trends.

So, all your lost sales cases for that hit product can be nipped at the bud because of a sudden spike in demand notification on the system prompting your action.

3. Data Analytics & Reporting

The cloud-based inventory management system applies data-driven insights to help businesses manage stock levels and forecast demand. Analytics included allow businesses to:

- Assess how well products are selling and which are slow movers.

- Predict the time that will have the highest sales by observing previously established trends.

- Assess stock levels for future sales based on profitability within a specified period.

Armed with data, businesses can make better choices, eliminate wastage, and ensure that the right products are ready at the right time.

4. Scalability & Flexibility

Your inventory management needs will change as your business expands. Cloud-based options allow for flexibility to:

- Scale operations whenever they reach new markets or warehouses.

- Integrates smoothly with e-commerce platforms, supply-chain tools, and accounting software.

- Deal with variations in demand that may be seasonal or arise unexpectedly.

Whatever your business is—a startup or an enterprise—cloud-based inventory management is the way to go. It's the one that grows with you, assuring a smooth and effective operation at every stage.

Benefits Of Cloud-Based Inventory Management

Cloud-based inventory management systems, unlike their unambitious predecessors, provide a vast set of benefits that can streamline operations and promote company growth.

1. Real-Time Data Access

In real-time cloud inventory management, stock levels are updated instantaneously, granting you instant access to the most accurate data. Therefore, you:

- Monitor inventory changes in real time.

- Prevent stock outs by getting low-stock alerts automatically.

- Make fast and accurate decisions to keep business running.

2. Cost Savings

A cloud-based system further reduces unnecessary costs by automating the inventory routine and reducing errors. This allows the businesses to:

- Prevent the incidence of overstocks or understocks, which cause wasted inventory and potential lost sales.

- Reduce labor costs by automating all the manual inventory chores.

- Make cost-effective purchasing decisions and prevent excessive spending on inventory.

3. Accurate Demand Forecasting

These systems rely on the analysis of sales data covering a certain period, giving an organization insight into the likely future demand. Thus:

- Good inventory planning can be done to meet customer requirements.

- Evidence-based investment in stock.

- There is a low risk of surplus inventory or shortage of products.

4. Faster Order Fulfillment

This orderly inventory system constitutes quicker order processing and shipping attributed to the cloud-based inventory management, which is a boost to customer satisfaction. These include:

- Search for stock easily across warehouses or locations.

- Accelerate order processing, which minimizes manual errors.

- Ensure seamless integration with sales channels for hassle-free fulfillment.

Cloud Inventory Platform Features

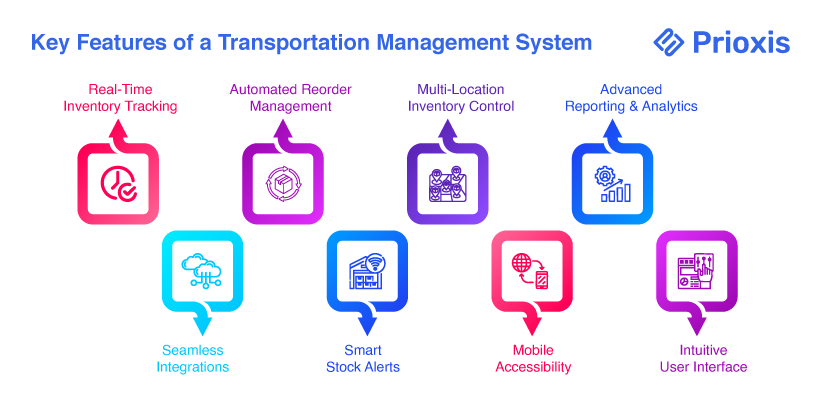

Cloud inventory platforms go beyond stock management capabilities. They come in all-encompassing solutions to streamline operations, improve efficiency, and lead to business expansion. Here are some of the essential features to look out for when selecting an inventory system to maximize its potential:

- 1. Real-Time Inventory Tracking

Emphasizing the amounts of stock at minute intervals using real-time inventory tracking includes updates on stock levels, movements, and availability in a robust cloud inventory system. It will thus minimize errors and give accurate inventory counts.

- 2. Seamless Integrations

Your inventory platform should integrate with other important business tools, such as accounting software (QuickBooks), eCommerce platforms, and shipping carriers. This eliminates the manual entry process and keeps all operations involved in seamless workflows.

- 3. Automated Reorder Management

Your stock would never go unexpectedly into deficit, and there are automated reorder points whereby the system sends alerts whenever the stock reaches a certain level and initiates a refilling mechanism so that a lot of downtime isn't noticed when stock is short.

- 4. Smart Stock Alerts

Smart stock alerts warn you whenever the level of stock is below or no stock is available so that you can take immediate action. This way, you could ensure that no sales are lost because of a supply chain problem.

- 5. Multi-Location Inventory Control

In a situation where an application manages several warehouses or locations, a cloud inventory platform will give full visibility and control of stock spread across different places so that allocation, transfer, and optimization can take place at different sites seamlessly.

- 6. Mobile Accessibility

With such a mobile-friendly cloud inventory solution, stock can be managed even from outside the firm. Whether using a smartphone or tablet, business owners and their employees can access real-time inventory data from anywhere.

- 7. Advanced Reporting & Analytics

Data-driven decision-making is the blood and oxygen to be successful in business today. Therefore, you will need to find systems that provide excellent customizable reports, dashboards, and analytics on different types of inventory trends, as well as forecasting demand and overall performance.

- 8. Intuitive User Interface

Always ensure ease-of-use. A well-designed cloud inventory platform must have an intuitive interface to enable easy navigation without consuming too much time in the learning curve. There also must be adequate training materials, tutorials, and customer support to facilitate easy adoption.

Future Trends in Cloud Inventory Management

High-tech innovations such as Artificial Intelligence (AI), the Internet of Things (IoT), and blockchain are defining the future of cloud inventory management. They make it capable of real-time tracking, predictive maintenance, and improved transparency in the supply chain discrepancies in management. These trend-enhancing features will inspire the evolution of the next generation of inventory management.

1. AI and ML Making Smarter Inventory Decisions

AI and ML are creating new looks in inventory management by enabling the following for businesses:

- Forecasting demand and disruptions within the supply chain through predictive analytics

- Real-time data mining from multiple sources on decision making.

- Dynamic adjusting to demand changes for stock optimization.

For instance, a Fortune 100 company in Germany integrated AI-based logistics in more than 400 warehouses to leverage inventory accuracy and operating efficiency.

2. Real-Time Tracking with IoT Integration

The Internet of Things (IoT) underpins inventory visibility across smart devices for tracking, including using RFID, Bluetooth, and 5G UC. These include:

- Immediate monitoring of stock movement across the warehouses and supply chains.

- With automatic RFID reading in real time, manual error can only be minimized.

- Order accuracy fulfillment is improved but will reduce inventory inaccuracies by about 20%-30%.

With IoT, an organization is enabled to keep up-to-date and accurate inventory data, indicating time stock optimization and smooth operations.

3. Supply Chain Transparency by Blockchain Technology

Blockchain technology makes a major change in inventory management by providing;

- A decentralized and inalterable ledger for various inventory transactions.

- Greater transparency for traceability aspects, thereby boosting consumer trust.

- An unchangeable record of supply chain data preventing fraud and errors.

Blockchain thus permits the business to confirm the sources of products against their authenticity, besides preserving a secure and trustworthy inventory record. It minimizes risk and inefficiency within the supply chain.

Conclusion

The future age of smart, efficient, and highly transparent operations in cloud inventory management is powered by AI, IoT, and blockchain technology. Only businesses that apply these technologies can get a leg up on competition by enabling themselves to track in real time, optimize inventory levels, and maintain supply chain integrity.

We at Prioxis are providing state-of-the-art cloud inventory solutions suited to your needs. Whether you aim to elevate automation, increase accuracy, or leverage the latest technology, our responsive platform will help you seize inventory management.

Want to leverage next-gen technology for your inventory? Talk to Prioxis today to start your journey toward a smarter and more efficient inventory system!