Expertise

In today’s fast-paced retail and eCommerce landscape, AI-driven inventory management is revolutionizing how businesses track, control, and optimize their stock levels. AI is set to contribute $1.3 trillion to the global economy in the next 20 years. Therefore, businesses that incorporate AI within their supply chain operations will be competitive because these organizations can work smarter and faster than their human counterparts.

In this article, we present the trend toward higher adoption rates of AI in warehouse automation, from just 11% in 2019 to an enormous 75% by 2030. This we will discuss amongst other aspects how systems powered with AI improve demand forecasting, minimize stockouts, and overall streamline supply chains.

Whether AI is new to you or you are only polishing your strategy for managing your inventory with the latest technologies, this guide will help you grasp the sheer transforming power of artificial intelligence in inventory control.

The Role of AI in Inventory Management

AI is a game changer for inventory management; solving a lot of long-term issues, it presents intelligent, data-driven methods. In place of a process characterized by labor-intensive manual actions, organizations use AI-powered operations now to streamline operations, manage stock levels, and facilitate overall efficiency.

This includes areas such as retail, manufacturing, and logistics where AI plays its role in inventory management. For instance, in retail, it forecasts the demand of consumers such that it helps avoid stockouts and accumulation of excess stock. In manufacturing, the cargoed raw material is materialized for production planning. In logistics, AI reduces costs as well as timely deliveries with route optimization.

The impact of AI on inventory management is huge:

- Higher Accuracy: AI brings greater precision in data processing for massive datasets, thereby minimizing AI Inventory Forecasting errors and maintaining optimal stock levels.

- Monitoring in Real-time: AI always keeps track of the inventory assets, sales trends, and supply-chain transfers, allowing for forward-thinking decisions.

- Process Automation: Repetitive inventories of activities restoring and ordering can be handled by the AI-driven automated process so that employees can focus more on strategic goals.

- Cost Saving: AI saves costs for an organization by minimizing stock differences and maximizing levels in inventory.

- Better Customer Satisfaction: Products are available whenever needed, which creates a better experience for customers, thus increasing loyalty.

Now, inventory management is changing for everyone from a small business to a giant enterprise. More effective, less expensive, and more responsive to the changing demands of the market.

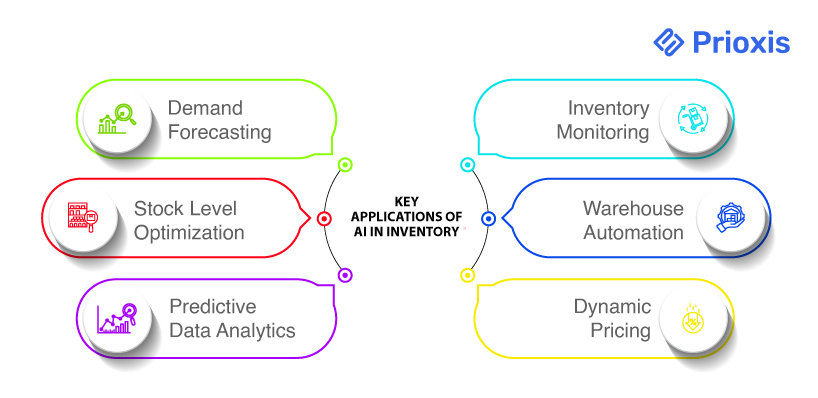

Key Applications of AI in Inventory Management

Where AI serves as a boon in inventory management, surely, it helps to optimize stock levels, minimize waste, and maximize customer satisfaction for a business. The AI-based solution provides real-time insights, process automation, and data-based operational decision-making for efficiency. The key applications of Artificial Intelligence in inventory management are as follows:

1. Demand Forecasting

With demand forecasting powered by AI, companies can accurately predict future product demand. This is facilitated through the study of historical sales data, market trends, seasonal variations, and customer behavior. With this kind of information, companies can maintain optimum stock levels to avoid the possibility of having too much stock which ties capital down, or too little stock which allows a loss of sales.

2. Stock Level Optimization

Artificial intelligence ensures stocks are adjusted on a real-time basis based on patterns of demand, suppliers' lead time, and real-time sales data. In this way, it always ensures there is little excess stock which could lead to storage costs or wastage, and avoidance of stockouts which may jeopardize customer satisfaction.

3. Predictive Data Analytics

Powerful data and machine learning employ AI by analyzing the more significant volumes of data related to inventory to anticipate possible disruptions in the supply chain. The analysis would aid the company in drawing patterns with logistics delays, issues with supplier performances, and changes in market demand so that it could improve its actions on precautionary measures to avoid causing damage.

4. Inventory Monitoring

Solutions for AI Inventory Tracking maintain real-time data on stock movement across different points- from store to warehouse and outlet. RFIDs, IoT Sensors, and barcode scanning in tandem with the AI-enabled platform integrated into the inventory tracking system would ensure high certainty and thus would have low chances of goods becoming misplaced, lost, or stolen. Businesses can track products at every supply chain level to maximize efficiency.

5. Warehouse Automation

AI-powered robots and automated warehouse systems improve order fulfillment by optimizing picking, packing, and restocking. Autonomous mobile robots reduce the chances of human error, increase processing speed, and improve storage efficiencies. AI-backed smart warehouse solutions allow companies to fulfill orders at a higher volume, with greater accuracy, and lower labor costs.

6. Dynamic Pricing

AI-based pricing models are dynamically adjusting prices driven by competitor pricing, customer behavior, demand elasticity, and macroeconomic factors. This ensures businesses remain competitive while maximizing profitability. AI algorithms can also determine the most effective pricing strategies for different customer segments to improve conversion rates and drive revenue.

Benefits of AI in Inventory Management

- Increased Efficiency: AI makes it possible to automate procedures, such as stock supervision, procurement, and demand forecasting, thus freeing manpower and rendering it more productive.

- Improved Accuracy: AI algorithms rely on many thousands of data items to forecast inventories accurately, which eliminates human errors and mismatches.

- Real-time Insights: AI allows constant analysis of the levels of inventory and sales trends along with supply chain movements with enterprises to take proactive and preventive steps against stock shortages or overstocking.

- Cost reduction: Stock optimization and automated operations for inventory internally reduce the waste and inefficiency associated with excess storage while effecting immense savings operationally.

- Customer service improvement: When it is AI-based, inventory management can potentially accumulate products in the time when they will be required without increasing the waiting period and will worsen the full experience in a shopping endeavor.

- Scalability: The AI-based inventory system can typically grow with a business, supporting its multi-location and multi-channel endeavors without the need to invest time and effort in endless manual work.

AI Inventory Management Implementation Challenges

Though AI-enabled inventory management can save a lot of time, costs, and errors, it does come with several challenges for enterprises willing to take the plunge into implementation. Understanding these challenges helps in a smooth transition into AI adoption.

The Quality and Availability of Data

Unlike the common misconception about AI being self-sustainable, it requires accurate and current data for it to perform proper predictions. With incomplete or faulty data, AI would make wrong predictions; hence the need for an investment in data cleansing and integration by businesses. This problem might also be more severe in such firms where not-so-extensive historical data are available, making AI forecasting particularly unyielding for such companies.

Very High Costs for Implementation

Such big sums are required for building software and hardware for AI, not to forget the training and onboarding of employees into the new system of mind of the AI. Cloud-based developments in AI are making things much easier and less expensive for companies including cloud-their software. Of course, smaller- and mid-sized businesses cannot always pay to put AI into action for their inventory management.

Need for Skilled People

AI-interested domain specialists have expertise in data science, machine learning, and automation. It becomes costly and difficult for companies, especially those new to this technology, to either recruit these specialists or up-skill their present employees to meet this demand.

Integration with Legacy Systems

Many businesses don't have the luxury of tearing down their existing legacy systems as they have already been utilizing these traditional tools for inventory management. Therefore, custom development with appropriate integration as well as transition planning would be necessary.

Security and Privacy Risks

Since an AI system processes huge volumes of sensitive inputs, cyber security becomes an issue. Adequate procedures have to be put in place for the prevention of any data breach and to protect the information of clients and organizations.

Real-world Applications

AI in Inventory Management has affected the other end-of-the-spectrum. It has enhanced operational efficiency, accuracy, and customer experience in its application throughout various industries. It is the real-world integration of AI into inventory systems that gives the most practical evidence for its effectiveness.

Amazon AI-Powered Warehouses

Amazon transformed warehouse operations after acquiring Kiva Systems (now Amazon Robotics) for $775 million in 2012. The firm deployed AI-powered robots for automated picking, packing, and inventory tracking. This has drastically improved the speed, accuracy, and cost-effectiveness of the order fulfillment process, which can now run at an unprecedented pace with the sheer number of orders coming in every day.

Optimizing Retail with LoweBots

Home improvement giant Lowe's developed autonomous robots called LoweBots. These AI-powered machines, using machine learning and computer vision, assist customers in locating items while monitoring, in real-time, inventory levels. The dual capability enhances stock accuracy and boosts shopper experience in-store.

AI for Intelligent Inventory Solutions by IBM Watson

IBM's Watson AI platform provides more than basic inventory tracking. It analyzes the real-time movement of inventory and the condition of shipping containers and proposes intelligent maintenance recommendations. Watson has helped various enterprises gain operational efficiency and reduce inventory costs.

Conclusion

Inventory management today, especially with AI, is no longer a luxury but is becoming a requisite due to changing conditions in various industries. Prioxis gives competitive advantages to companies, allowing them to operate smarter and make inventory decisions based on data. With its innovative ideas, Prioxis is determining the direction of intelligent inventory management.

Ready to transform your inventory management? Join hands with Prioxis today and give your business wings using AI-based solutions!